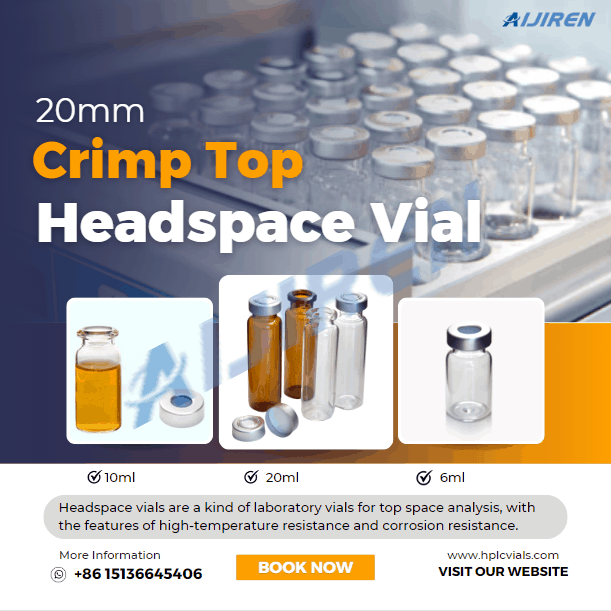

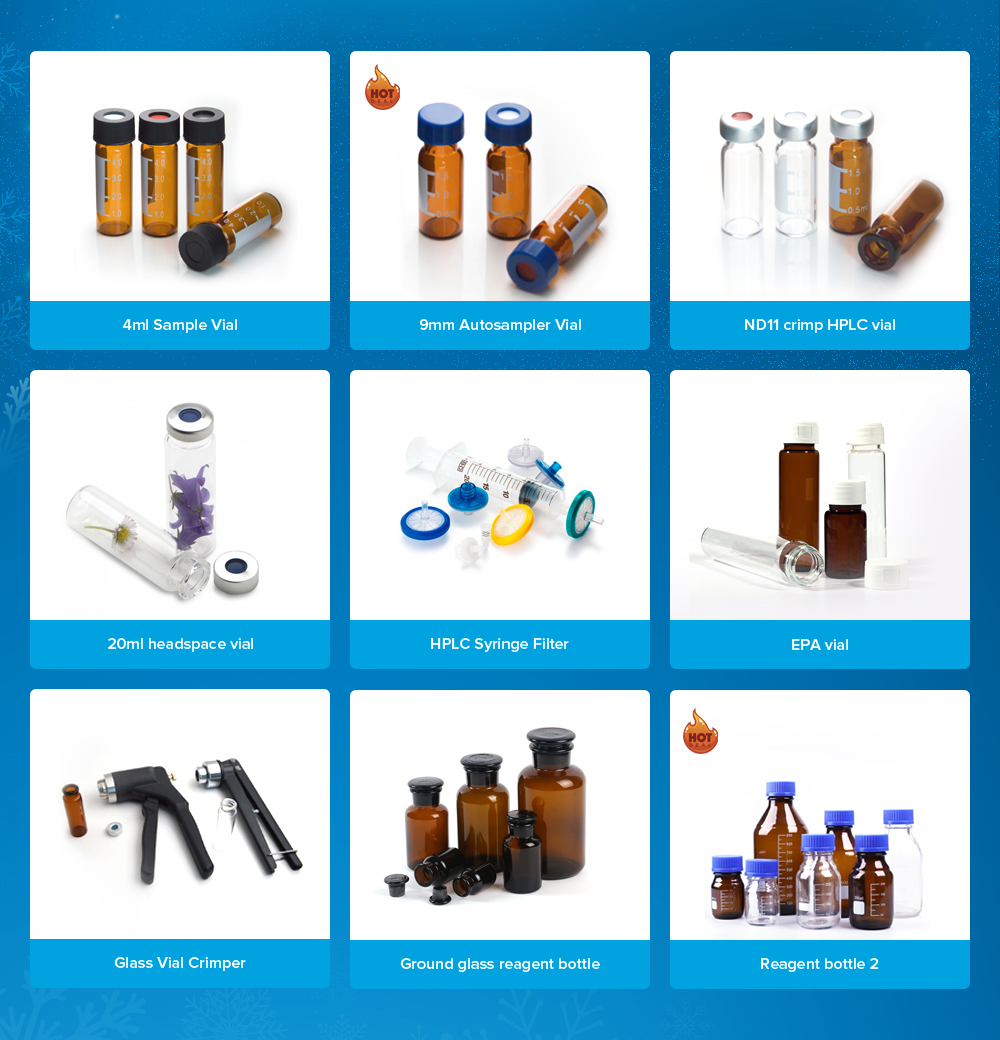

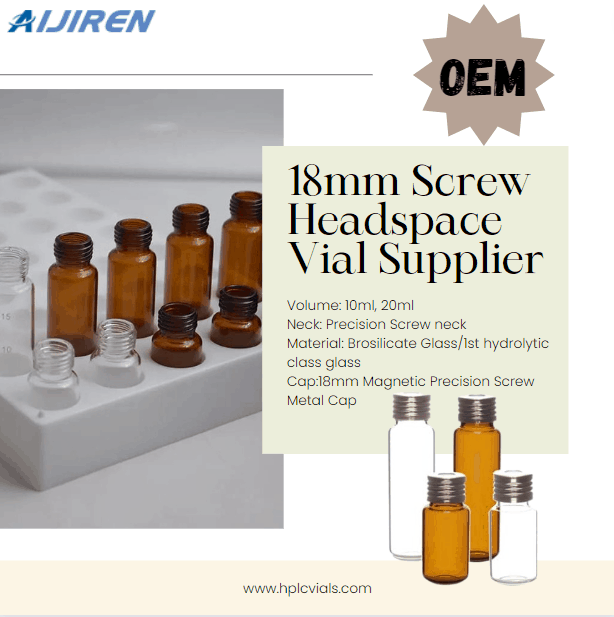

Headspace Vial Size Chart: 10ml 20ml Dimensions & Specifications Guide

Compare standard headspace vial sizes (6ml, 10ml, 20ml). Detailed dimensions including diameter, height, and neck finish for Agilent, PerkinElmer & Tekmar autosamplers. Factory direct pricing.

Standard Headspace Vial Dimensions & Measurement Chart

For precise autosampler configuration (PerkinElmer, Tekmar, Agilent), use the following technical measurements to prevent needle strikes and mechanical errors.

| Nominal Volume | Actual Capacity | Diameter (OD) | Height (H) | Cap Size | Bottom Type |

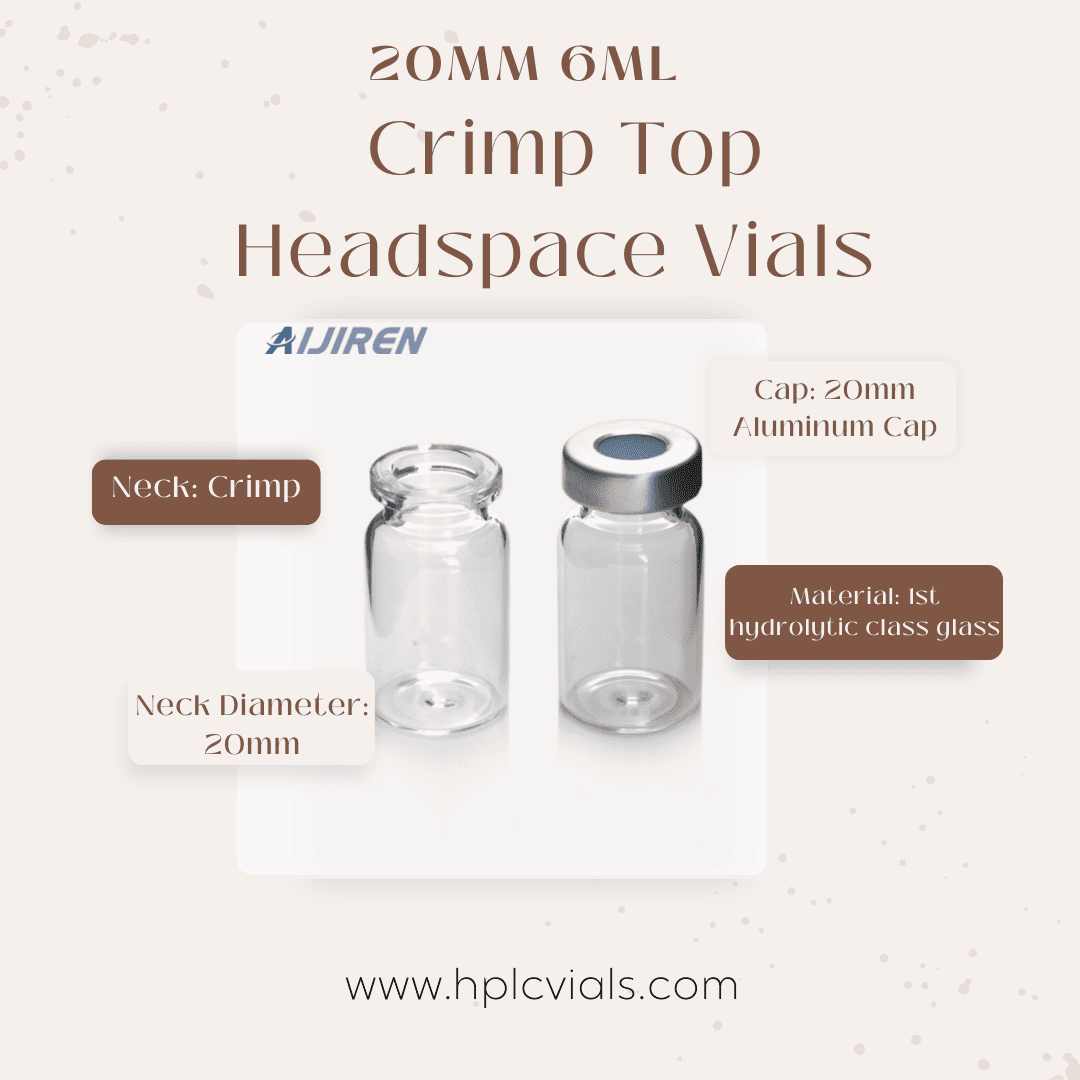

| 6mL Vial | ~8.5 mL | 22 mm | 38 mm | 20mm Crimp | Flat |

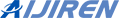

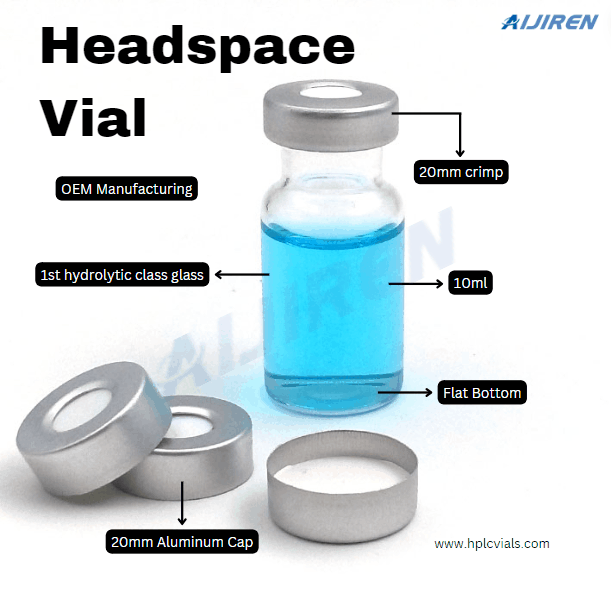

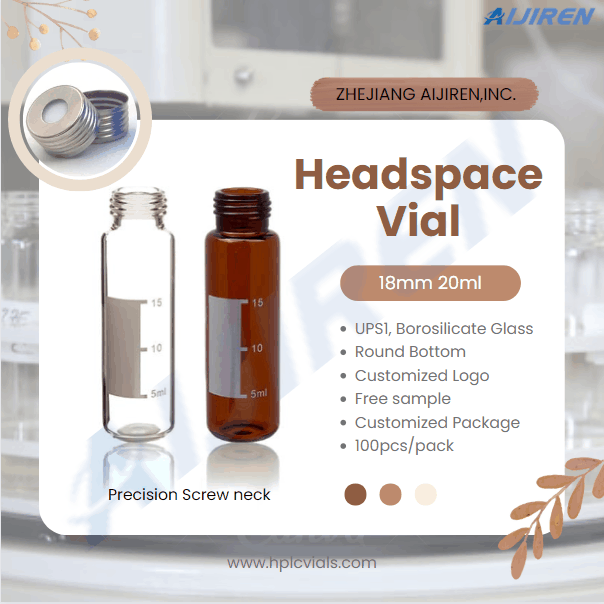

| 10mL Vial | ~12.2 mL | 22.5 mm | 46 mm | 20mm Crimp | Flat / Rounded |

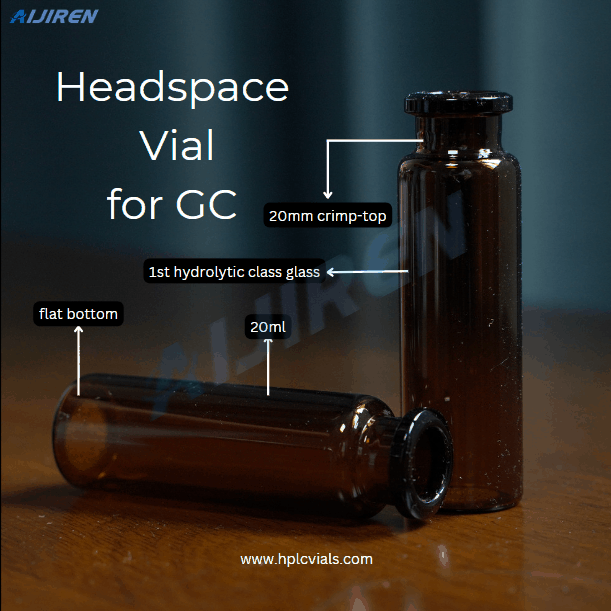

| 20mL Vial | ~22.6 mL | 22.5 mm | 75.5 mm | 20mm Crimp | Flat / Rounded |

Expert Selection Guide: 10mL vs. 20mL Vials

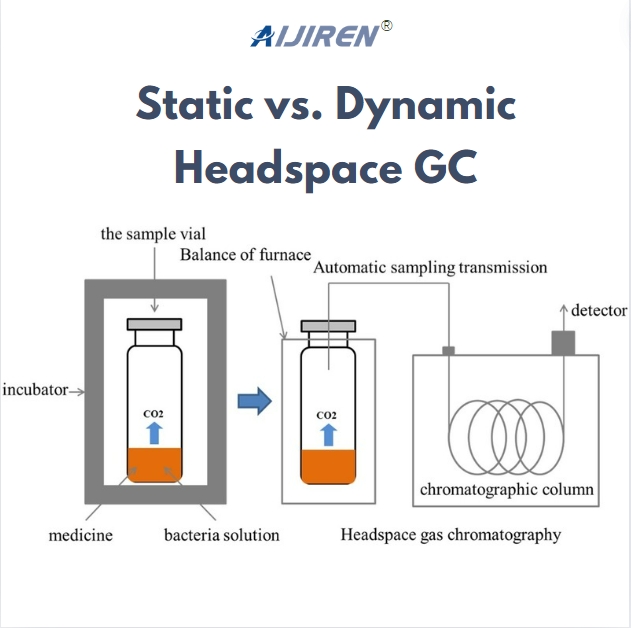

Understanding vial sizes is essential for optimizing sensitivity in VOC (Volatile Organic Compounds) analysis.

-

10mL Vials: Best for liquid samples requiring a higher concentration of volatiles in the headspace. A smaller headspace-to-sample ratio increases sensitivity for low-concentration analytes.

-

20mL Vials: The industry standard for larger sample volumes (5mL – 10mL). This vial volume provides an adequate safety buffer to manage internal pressure during high-temperature incubation.

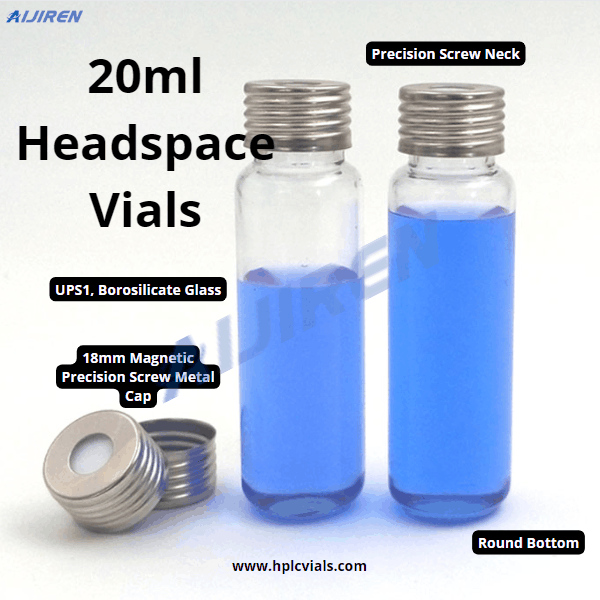

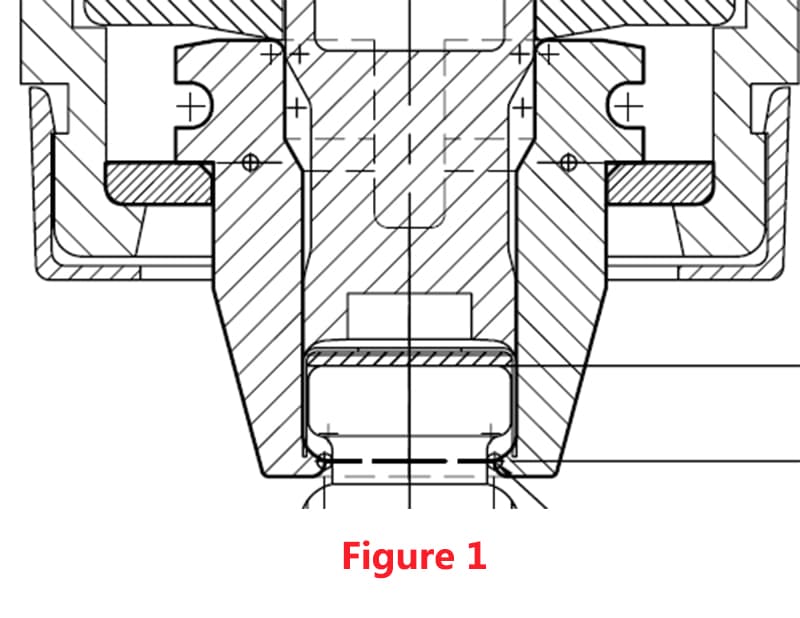

Engineering Design: Flat vs. Rounded Bottom

-

Rounded Bottom (DIN Style): Optimized for robotic autosamplers and magnetic pick-up. The rounded design allows the vial to self-center in the heating block, ensuring uniform thermal distribution and reproducible results.

-

Flat Bottom: Ideal for stationary incubation and manual sampling where stability on the lab bench is required.

Technical FAQ

-

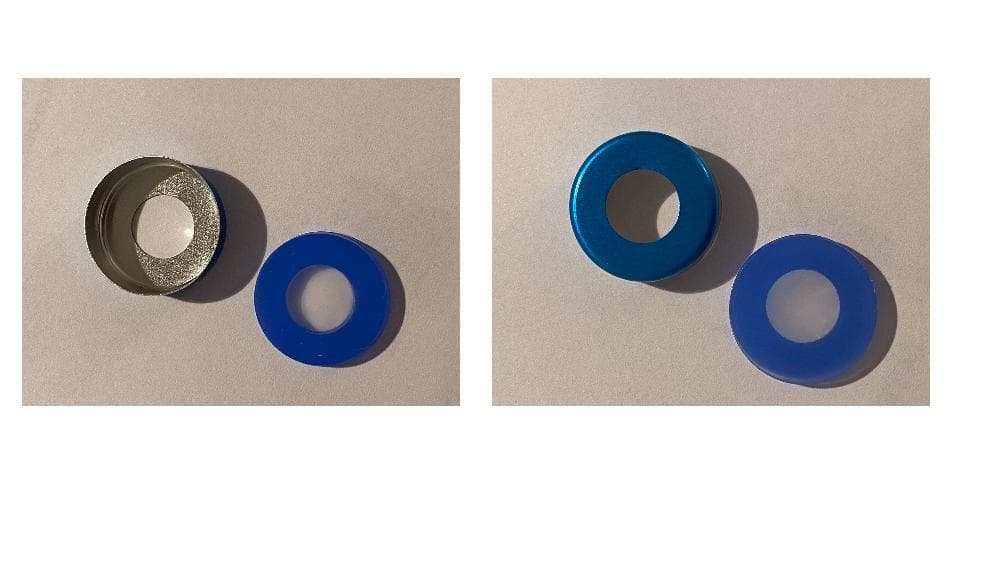

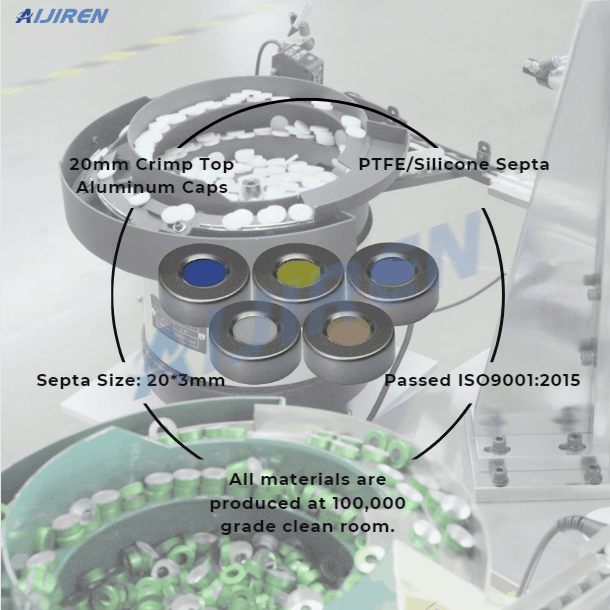

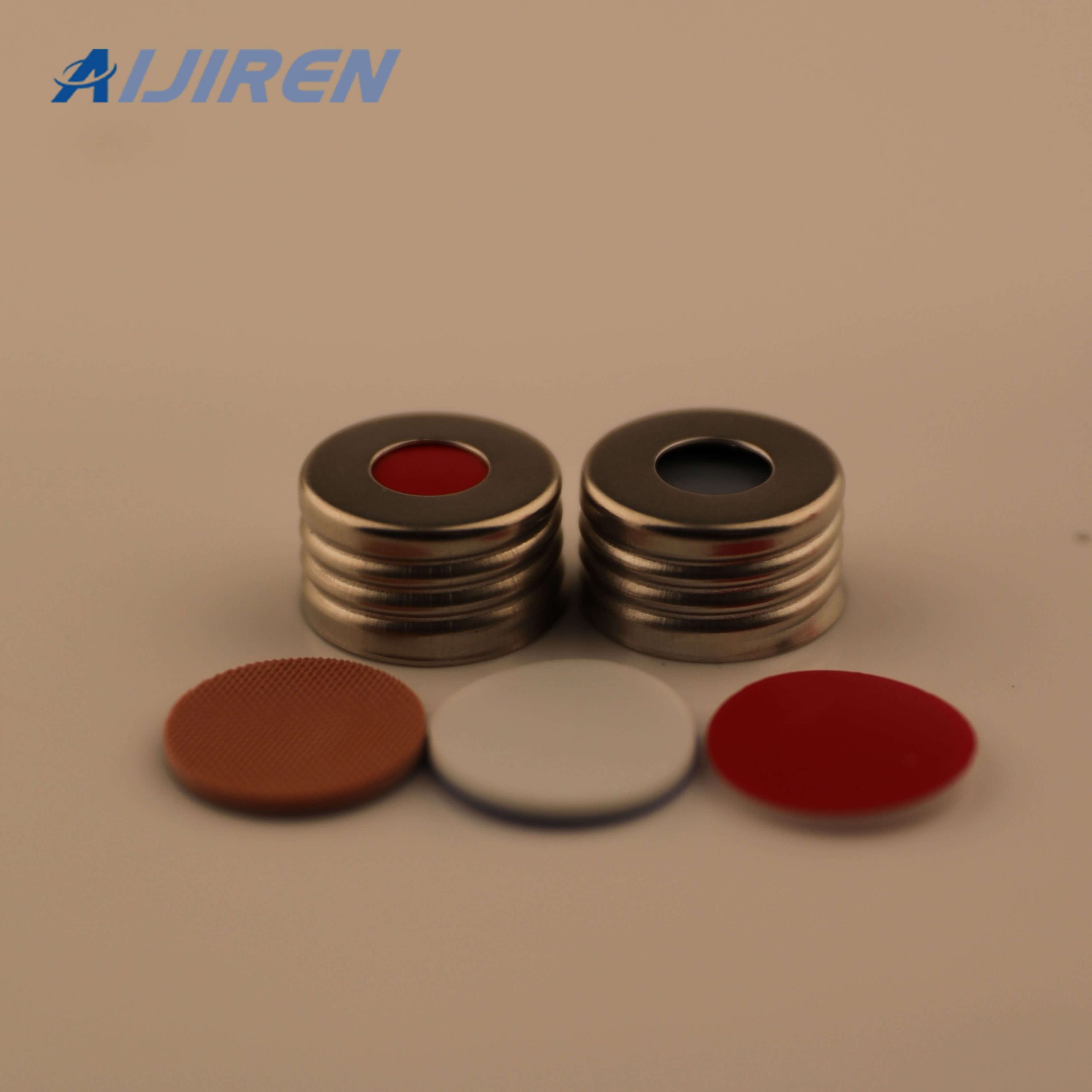

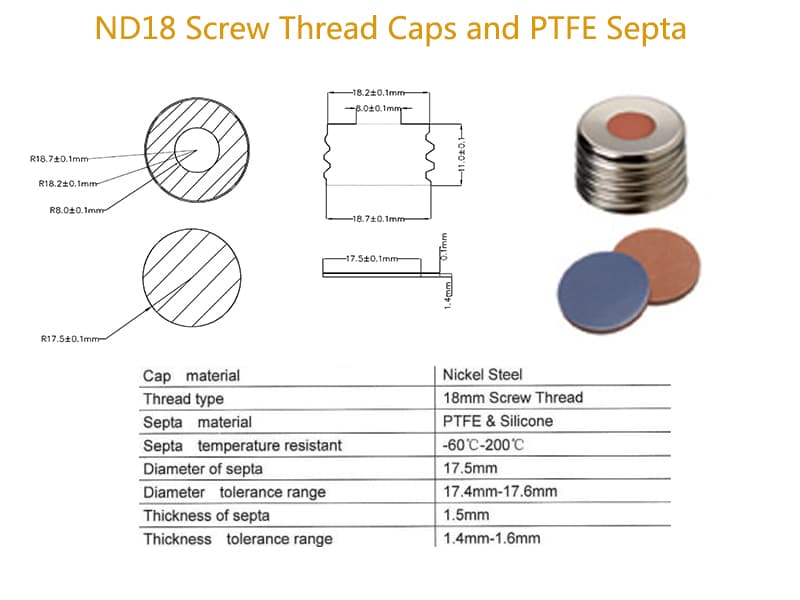

What is the neck finish on these headspace vials? Aijiren vials feature a 20mm beveled neck finish. This precision-molded design provides a superior seal with aluminum or bi-metal magnetic caps, crucial for high-pressure GC analysis.

-

Are these vials suitable for SPME? Yes, our vials are fully compatible with Solid Phase Microextraction (SPME). We recommend pairing them with our thin-septum caps to ensure smooth needle penetration.

-

How do I measure vial dimensions? Vial height is measured from the base to the top of the rim. The diameter is the outer dimension (OD) of the widest part of the glass body.