Behind every headspace vial lies a meticulous manufacturing process. Established manufacturers utilize top-tier borosilicate glass, ensuring durability and resistance to the demanding conditions of gas chromatography. With stringent quality checks, these manufacturers ensure that each vial meets the highest standards of precision

What is headspace vials?

Headspace vials, also known as gas chromatography (GC) vials, are specialized containers used in analytical chemistry for the analysis of volatile compounds in gas chromatography.

When analyzing volatile compounds, such as those found in liquids or solid samples, the headspace technique is commonly used. It involves extracting the volatile components by heating the sample in a sealed vial, which creates a headspace (gas) above the sample. The headspace vial is designed to securely hold the sample and maintain its integrity during the analysis.

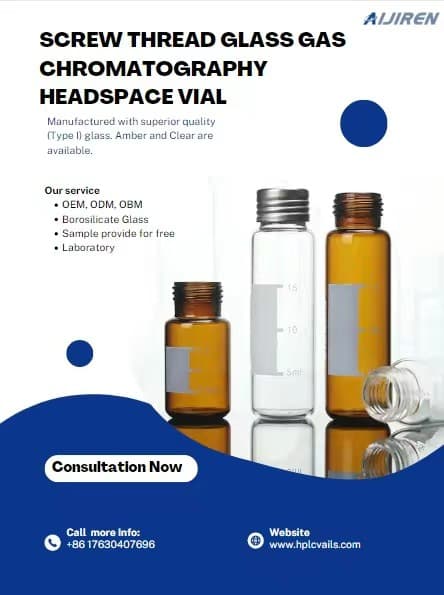

Headspace vials are typically made of glass and have a screw or crimp top to ensure an airtight seal. They come in various sizes, such as 10 mL or 20 mL, depending on the volume of the headspace needed for analysis. The vials may also have a septum, which is a rubber or silicone disk that acts as a seal and allows for the injection of a syringe needle to introduce the headspace sample into the gas chromatograph.

Headspace vials are an essential component in headspace gas chromatography, enabling the accurate and efficient analysis of volatile compounds in various industries, including pharmaceuticals, environmental analysis, food and beverage, forensic sciences, and more.

Headspace vial is a specialized container designed to analyze volatile organic compounds (VOCs). Unlike traditional vials, it focuses on the vapor phase or 'headspace' above the sample. This unique design allows for the extraction and analysis of the volatile fraction of a sample, minimizing interference from non-volatile components.

What are the characteristics of the headspace vials?

Headspace vials are specialized containers used in gas chromatography (GC) and headspace analysis. These vials are designed to contain samples that are analyzed for volatile compounds or gases. Here are some of the characteristics and features of headspace vials:

1.Material: Headspace vials are typically made from borosilicate glass, which is inert and can withstand the high temperatures and pressures associated with the headspace sampling process.

2.Volume: These vials come in various volumes, typically ranging from a few milliliters to several milliliters, depending on the application and the quantity of the sample.

3.Septa: Each headspace vial is sealed with a septum, which is a thin layer made of materials like silicone, PTFE (polytetrafluoroethylene), or a combination of materials. The septa provide a secure seal and can be pierced by the needle of the autosampler during the sampling process.

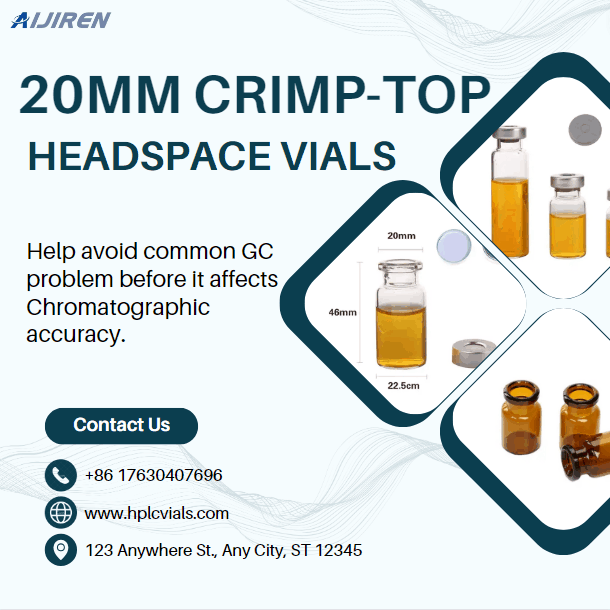

4.Thread Type: Headspace vials often feature a specific thread type to ensure a proper fit with the vial caps or closures. The most common thread type is the 18 mm crimp top, but other sizes and designs are also available.

5.Crimp Top: Many headspace vials have a crimp top design. This means that after filling the vial with the sample and placing a septum on top, a special crimper tool is used to crimp the aluminum seal around the vial neck, ensuring a tight and secure seal.

6.Round or Flat Bottom: Headspace vials can have either a round or flat bottom, depending on the specific requirements of the analysis method or the autosampler used.

7.Compatibility: Headspace vials are compatible with a variety of analytical instruments, including GC systems equipped with headspace samplers.

8.Pressure Resistance: Due to the nature of headspace analysis, where samples are heated to promote the release of volatile compounds, headspace vials must be able to withstand the pressure generated within the vial during the process.

9.Clear or Amber: Headspace vials are available in clear or amber colors. Amber vials provide protection against light-sensitive samples, minimizing potential degradation caused by light exposure.

10.Cleanliness: Headspace vials are typically cleaned and processed to ensure that they are free from contaminants that could interfere with the analysis.

Overall, headspace vials are designed to provide a secure and reliable container for samples during headspace analysis, ensuring accurate and reproducible results in gas chromatography applications.

What is the material of the headspace vials?

The material commonly used for headspace vials is borosilicate glass. Borosilicate glass is preferred for its inert properties, which means it does not react with most chemicals or introduce contaminants that could interfere with the analysis. Additionally, borosilicate glass can withstand the high temperatures and pressures associated with headspace sampling and gas chromatography processes. This makes it a suitable choice for containing samples that are analyzed for volatile compounds or gases in analytical laboratories.

Headspace vials production process

The production process for headspace vials involves several steps to manufacture high-quality vials suitable for containing samples and undergoing headspace analysis in gas chromatography (GC) applications. While specific processes may vary depending on the manufacturer and the type of vial, here is a general overview of the production process for headspace vials:

1. Raw Materials:

Borosilicate Glass: The primary material used for headspace vials is borosilicate glass due to its inert properties and ability to withstand high temperatures and pressures.

Septa: Septa, typically made of silicone, PTFE, or a combination of materials, are used as the sealing material for headspace vials.

2. Glass Tube Formation:

Glass Melting: Borosilicate glass is melted in a furnace at high temperatures.

Tube Formation: The molten glass is drawn into tubes of the desired diameter and thickness using a glass drawing machine.

3. Tube Cutting and Shaping:

Tube Cutting: The glass tubes are cut into specific lengths to form individual vials.

Shaping: The cut glass tubes may undergo further shaping or manipulation to achieve the desired dimensions and geometry for the vials.

4. Annealing:

Heat Treatment: The glass vials are subjected to a controlled heating and cooling process called annealing. This process relieves internal stresses in the glass and enhances its mechanical strength and resistance to thermal shock.

5. Surface Treatment:

Cleaning: The vials are thoroughly cleaned to remove any contaminants or residues from the manufacturing process.

Coating: Some vials may undergo a coating process to enhance their chemical resistance or provide specific functional properties.

6. Septa Installation:

Septa Insertion: The septa are inserted into the vial caps or closures using specialized equipment. This ensures a proper seal and allows for the puncturing of the septa during the headspace sampling process.

7. Assembly and Packaging:

Vial Assembly: The vials, along with their caps or closures, are assembled into final products ready for packaging.

Packaging: The vials are packaged in trays, boxes, or other suitable containers for storage, transportation, and distribution to customers.

8. Quality Control:

Inspection: The vials undergo rigorous quality control inspections to ensure they meet specified dimensional tolerances, cleanliness standards, and performance criteria.

Testing: Random samples of vials may be subjected to various tests, such as leak testing, pressure testing, or performance testing, to validate their quality and functionality.

9. Certification and Documentation:

Certification: The vials may be certified to meet international standards or regulatory requirements, such as ISO standards or specific industry guidelines.

Documentation: Detailed documentation, including product specifications, batch records, and quality certificates, is prepared to support traceability and compliance with quality management systems.

In summary, the production process for headspace vials involves the careful selection of raw materials, precision manufacturing techniques, quality control measures, and documentation to ensure the production of high-quality vials suitable for headspace analysis applications in analytical laboratories.

What is the function of the headspace vials?

Headspace vials serve a crucial role in the process of headspace analysis, a technique commonly used in gas chromatography (GC). The primary function of headspace vials is to provide a sealed and controlled environment for the analysis of volatile compounds or gases present in the headspace (the gas phase above the sample) of a sample.

Here are the key functions of headspace vials:

1.Sample Containment: Headspace vials contain the sample being analyzed. The sample is typically a liquid or solid that may contain volatile compounds. The vial is sealed with a cap or closure to prevent the escape of volatile components into the atmosphere.

2.Heating and Equilibration: The headspace vial, along with its sealed contents, is heated to promote the release of volatile compounds from the sample into the headspace. This heating process allows the system to reach equilibrium, ensuring that the volatile components in the headspace are representative of those in the original sample.

3.Sampling Interface: The headspace vial interfaces with an autosampler or manual injection system. A syringe or needle is used to extract a sample of the headspace gas for injection into the gas chromatograph for analysis.

4.Seal Integrity: Headspace vials have a septum (a thin, typically rubber or silicone disk) that serves as a seal. This septum allows a syringe needle to puncture the vial for sample extraction without compromising the overall seal integrity. After sampling, the septum reseals the vial.

5.Preventing Contamination: The vial material, often borosilicate glass, is chosen for its inert properties, ensuring that it does not introduce contaminants that could interfere with the analysis of volatile compounds.

6.Pressure Regulation: Headspace vials must withstand the pressure generated during the heating and equilibration phase. The vials are designed to handle the pressure changes without leaking or breaking.

7.Compatibility with GC Systems: Headspace vials are designed to be compatible with gas chromatography systems equipped with headspace sampling capabilities.

Overall, headspace vials play a critical role in facilitating the accurate and reproducible analysis of volatile compounds in a variety of samples, including pharmaceuticals, food products, environmental samples, and more. They provide a controlled environment for the sampling process, ensuring that the gas phase analyzed is representative of the volatile components present in the original sample.

What is the use of the headspace vials?

The use of headspace vials is primarily associated with headspace analysis, a technique employed in analytical chemistry, particularly in gas chromatography (GC). Here's a breakdown of the main uses and applications of headspace vials:

1.Analysis of Volatile Compounds: Headspace vials are utilized to analyze volatile and semi-volatile compounds present in various matrices, such as liquid, solid, or even gaseous samples. By heating the sample and allowing volatile compounds to equilibrate into the headspace above it, these compounds can be subsequently sampled and analyzed by GC.

2.Pharmaceutical Applications: In the pharmaceutical industry, headspace analysis can be used to detect residual solvents in drug formulations, monitor the stability of drug products, and ensure the absence of contaminants.

3.Food and Beverage Industry: Headspace analysis is crucial for assessing the flavor and aroma profiles of food and beverage products. It can be used to analyze volatile compounds responsible for the characteristic flavors and odors in various food products, such as wine, beer, coffee, and spices.

4.Environmental Monitoring: Headspace vials can be employed in environmental monitoring to analyze volatile organic compounds (VOCs) in air, water, or soil samples. This is important for assessing environmental contamination and monitoring compliance with environmental regulations.

5.Forensic Analysis: In forensic science, headspace analysis can be used to analyze volatile compounds in evidence samples, such as fire debris analysis or the detection of volatile compounds in biological samples.

6.Quality Control and Research: Headspace analysis is widely used in research and quality control laboratories across various industries to study the composition of volatile compounds in samples, investigate chemical reactions, assess product quality, and develop new analytical methods.

7.Safety and Compliance: In industries where the presence of certain volatile compounds may pose safety concerns or regulatory compliance issues, headspace analysis provides a reliable method for detecting and quantifying these compounds.

In summary, the primary use of headspace vials is to facilitate the collection, containment, and subsequent analysis of volatile compounds in various samples using headspace analysis techniques. This method offers a non-destructive and highly sensitive approach to characterizing the volatile profile of samples, making it invaluable in a wide range of applications across different industries.

What's the selling point of the headspace vials?

The selling points of headspace vials revolve around their design features, functionality, and the advantages they offer for headspace analysis applications in gas chromatography (GC). Here are some of the key selling points of headspace vials:

1.Inertness: Headspace vials are typically made from borosilicate glass, a material known for its inert properties. This ensures that the vials do not react with the sample or introduce contaminants, thereby preserving the integrity of the sample and the accuracy of the analysis.

2.Seal Integrity: The vials come with septa that provide a reliable seal, preventing the escape of volatile compounds and ensuring that the headspace gas is representative of the sample. The septa also allow for repeated punctures by syringe needles without compromising the seal.

3.Pressure Resistance: Headspace vials are designed to withstand the pressure changes that occur during the heating and equilibration phases of headspace analysis, ensuring safety and reliability during the analysis process.

4.Compatibility: These vials are compatible with a wide range of GC systems equipped with headspace sampling capabilities, offering versatility and ease of integration into existing analytical workflows.

5.Quality and Consistency: Headspace vials are manufactured to stringent quality standards, ensuring consistency in dimensions, sealing properties, and overall performance. This reliability is essential for obtaining consistent and reproducible analytical results.

6.Versatility: Headspace vials can accommodate various sample types, including liquids, solids, and even volatile gases, making them suitable for a wide range of applications across different industries.

7.Ease of Use: The vials are designed for easy handling and compatibility with automated sampling systems, simplifying the sample preparation and analysis process.

8.Safety: The design and materials used in headspace vials prioritize safety, minimizing the risk of sample contamination, leaks, or other issues that could compromise the analytical process or pose safety hazards.

9.Cost-Effective: Given their durability, reliability, and compatibility with analytical instruments, headspace vials offer a cost-effective solution for headspace analysis applications, providing value for money in terms of performance and longevity.

Overall, the selling points of headspace vials emphasize their reliability, compatibility, safety, and performance advantages for headspace analysis applications, making them a preferred choice for researchers, analysts, and laboratory professionals conducting GC-based analyses of volatile compounds.

A description of the advantages of a headspace vials

Headspace vials play a pivotal role in headspace analysis, a technique widely utilized in gas chromatography (GC) for the analysis of volatile and semi-volatile compounds in samples. Here's a focused description of the advantages associated with headspace vials:

1.Sample Preservation: One of the primary advantages of headspace vials is their ability to maintain the integrity of the sample. Made from inert materials like borosilicate glass, these vials ensure that the sample remains uncontaminated, thereby preserving its original composition for accurate analysis.

2.Enhanced Sensitivity: By allowing volatile compounds to volatilize and equilibrate in the headspace above the sample, headspace vials facilitate the analysis of low-level volatile compounds. This enhances the sensitivity of the analysis, making it possible to detect and quantify trace amounts of volatile analytes that might be challenging to measure directly.

3.Reduced Matrix Interference: The headspace technique minimizes the interference from complex sample matrices, such as solid or viscous samples, by focusing on the volatile and semi-volatile compounds present in the headspace. This selective analysis reduces the need for extensive sample cleanup or pre-treatment, simplifying the analytical process.

4.Safety and Convenience: The design of headspace vials, including the use of septa for sealing, ensures a secure and leak-free environment for the sample. This minimizes the risk of exposure to hazardous or volatile samples, enhancing safety in the laboratory and simplifying the sample handling process.

5.Versatility in Sample Types: Headspace vials can accommodate various types of samples, including liquids, solids, and powders. This versatility makes them suitable for a wide range of applications across different industries, from pharmaceuticals and food analysis to environmental and forensic sciences.

6.Consistency and Reproducibility: The use of headspace vials ensures consistent sample preparation and analysis conditions, leading to reproducible results. This consistency is essential for method validation, quality control, and research applications where reliable and repeatable data are crucial.

7.Efficiency in Automation: Headspace vials are compatible with automated sampling systems and GC instruments equipped with headspace capabilities. This compatibility facilitates high-throughput analysis, reduces manual intervention, and improves the overall efficiency and productivity of the analytical workflow.

8.Economic Benefits: The headspace technique using headspace vials can be more cost-effective compared to other sample preparation methods. It eliminates the need for extensive sample derivatization or cleanup steps, saving both time and resources in the analytical process.

In summary, headspace vials offer several distinct advantages, including sample preservation, enhanced sensitivity, reduced matrix interference, safety, versatility, reproducibility, automation compatibility, and cost-effectiveness. These advantages make headspace vials a preferred choice for researchers, analysts, and laboratory professionals conducting headspace analysis in various industries.

What value does the headspace vials bring to the customer to solve what problem?

Headspace vials bring several key values to customers, particularly in the analytical and research sectors, by addressing specific challenges and problems associated with the analysis of volatile compounds. Here's a breakdown of the value proposition of headspace vials and the problems they help solve:

1.Value Proposition:

Accuracy and Precision: By providing a controlled environment for the volatilization and equilibration of volatile compounds, headspace vials enable accurate and precise analysis, ensuring reliable data and informed decision-making.

2.Safety and Compliance: The secure sealing and containment properties of headspace vials minimize the risk of exposure to hazardous or volatile substances, enhancing safety in the laboratory and ensuring compliance with regulatory requirements.

3.Efficiency and Productivity: The compatibility of headspace vials with automated sampling systems and GC instruments facilitates high-throughput analysis, streamlines workflows, and reduces manual intervention, thereby improving efficiency and productivity.

4.Versatility and Adaptability: The ability of headspace vials to accommodate various sample types and volumes makes them versatile solutions that can be tailored to meet specific application requirements or analytical challenges.

5.Cost-Effectiveness: By eliminating the need for extensive sample preparation, cleanup, or derivatization steps, headspace vials offer a cost-effective solution that saves both time and resources in the analytical process.

6.Problems Addressed:

Sample Containment and Integrity: The sealed and inert environment provided by headspace vials addresses the problem of preserving sample integrity and preventing contamination or degradation, particularly for volatile compounds that may be susceptible to environmental factors.

7.Handling of Volatile Compounds: The specialized design of headspace vials facilitates the handling and analysis of volatile compounds, addressing challenges related to sample volatility, evaporation, or instability.

8.Complex Sample Matrices: The selective nature of headspace analysis using headspace vials minimizes interference from complex sample matrices, addressing challenges associated with the analysis of samples that contain multiple components or matrix effects.

9.Safety Concerns: The safety features of headspace vials, including secure sealing and containment, address concerns related to the handling, storage, or disposal of hazardous or volatile substances, ensuring a safer working environment for laboratory personnel.

10.Analytical Challenges: The consistent performance and reliability of headspace vials address analytical challenges related to the detection, quantification, or identification of volatile compounds in various samples, providing a robust solution for complex analytical tasks.

In summary, the value of headspace vials lies in their ability to provide accurate, safe, efficient, and cost-effective solutions for the analysis of volatile compounds, addressing specific challenges and requirements in analytical chemistry, research, quality control, and other applications. By solving these problems, headspace vials contribute to improved analytical workflows, better data quality, enhanced safety, and overall operational excellence for customers across different industries and sectors.

Advantages and characteristics of headspace vials for other products

Headspace vials are specialized containers primarily used in headspace analysis techniques, especially in gas chromatography (GC). While their primary application is in analytical chemistry, the advantages and characteristics of headspace vials can also be beneficial for other products or industries. Here's a look at how the advantages and characteristics of headspace vials can be relevant to other contexts:

Advantages:

1.Preservation of Volatiles: The primary advantage of headspace vials is their ability to preserve volatile and semi-volatile compounds without direct contact with the sample. This feature can be beneficial for products that contain volatile components that need to be preserved or analyzed separately.

2.Safety and Containment: The sealed design of headspace vials ensures the containment of volatile compounds, reducing the risk of exposure, contamination, or evaporation. This characteristic can be valuable in industries where handling or storing volatile substances safely is a priority.

3.Versatility: The ability of headspace vials to accommodate various sample types, including liquids, solids, and powders, makes them versatile containers. This versatility can be advantageous in industries that require flexible and adaptable sample storage or analysis solutions.

4.Consistency and Reproducibility: The consistent design and sealing properties of headspace vials contribute to reproducible results, which can be essential for quality control, product development, or research applications in various industries.

5.Compatibility with Automation: The compatibility of headspace vials with automated sampling systems can streamline processes, improve efficiency, and reduce manual handling, which can be beneficial in production environments or high-throughput applications.

Characteristics:

1.Inertness: Headspace vials are typically made from inert materials like borosilicate glass, ensuring compatibility with a wide range of substances without the risk of interaction or contamination.

2.Seal Integrity: The design of headspace vials includes features like septa for secure sealing, ensuring the integrity of the sample and preventing leaks or contamination.

3.Pressure Resistance: Headspace vials are designed to withstand the pressure changes associated with heating and equilibration processes, ensuring safety and reliability during analysis or storage.

4.Size and Volume Options: Headspace vials are available in various sizes and volumes, allowing for customized solutions to meet specific requirements or applications.

5.Quality and Compliance: Headspace vials are manufactured to stringent quality standards, ensuring consistent performance and compliance with regulatory requirements in relevant industries.

In summary, while headspace vials are primarily associated with analytical applications in chemistry and chromatography, their advantages and characteristics related to sample preservation, safety, versatility, consistency, and automation compatibility can be beneficial for other products or industries that deal with volatile compounds, require secure containment, or seek reliable and adaptable sample storage solutions.

What economic benefits can headspace vials bring?

Headspace vials can offer several economic benefits to laboratories, research institutions, and industries that rely on the analysis of volatile compounds. Here's a look at some of the economic advantages associated with the use of headspace vials:

1.Cost Savings on Sample Preparation: One of the primary economic benefits of using headspace vials is the potential cost savings on sample preparation. Headspace analysis eliminates the need for extensive sample cleanup, derivatization, or other pre-treatment steps that may be required for direct injection methods. This can result in reduced labor costs, lower consumption of reagents and solvents, and overall savings in sample preparation expenses.

2.Increased Efficiency and Throughput: The compatibility of headspace vials with automated sampling systems and GC instruments equipped with headspace capabilities can significantly increase analytical throughput. Automated sample handling and analysis can lead to higher sample processing rates, reduced turnaround times, and increased laboratory productivity, thereby maximizing the utilization of resources and generating cost savings.

3.Reduced Maintenance and Downtime: The robust design and reliable performance of headspace vials can contribute to reduced instrument downtime and maintenance costs. By minimizing sample carryover, contamination, or instrument malfunctions associated with challenging samples, headspace vials help maintain the integrity and longevity of GC systems, reducing the frequency and cost of maintenance activities.

4.Quality Control and Compliance: The accurate and reproducible results obtained using headspace vials can enhance quality control processes, ensuring compliance with regulatory requirements and industry standards. By minimizing the risk of errors, rework, or non-compliance issues, headspace vials can help avoid potential fines, penalties, or reputational damage, thereby protecting the economic interests of organizations.

5.Resource Optimization: The efficient use of headspace vials for targeted analysis of volatile compounds can optimize the allocation of resources, including personnel, equipment, and consumables. By focusing on specific analytes or applications that yield the highest economic value or strategic importance, organizations can prioritize their investments and resource allocation more effectively, maximizing return on investment (ROI).

6.Market Differentiation and Competitive Advantage: For businesses operating in competitive markets, the ability to offer accurate, reliable, and cost-effective analytical services using headspace vials can be a significant differentiator. By leveraging advanced analytical techniques and innovative solutions, organizations can enhance their market positioning, attract new customers, and create additional revenue streams, contributing to long-term economic growth and sustainability.

In summary, the economic benefits of headspace vials stem from their ability to streamline sample preparation, enhance analytical efficiency, improve quality control, optimize resource allocation, and create competitive advantages for organizations. By reducing costs, increasing productivity, and ensuring compliance, headspace vials can deliver tangible economic value and contribute to the overall success and profitability of laboratories and businesses across various industries.

Seven Applications of Headspace Vials

l Flavor and Fragrance Analysis: Essential for food and cosmetic industries to understand and control product profiles.

l Pharmaceutical Quality Control: Detecting residual solvents and ensuring adherence to regulatory standards.

l Environmental Monitoring: Assessing contaminants in air, water, and soil samples.

l Petrochemical Assessments: Analyzing volatile components in crude oils and derivatives.

l Beverage Quality Assurance: Ensuring consistency and detecting contaminants in beverages

l Forensic Investigations: Extracting volatile residues from crime scenes for analysis.

l Material Emission Studies: Understanding volatiles emitted from various materials over time

Ten Common Types of Headspace Vials

l Clear Glass Vials

l Amber Glass Vials

l ·Screw Top Vials

l ·Crimp Top Vials

l ·Flat Bottom Vials

l ·Round Bottom Vials

l ·Magnetic Screw Cap Vials

l ·PTFE/Silicone Septum Vials

l ·Pre-slit Septum Vials

l ·High-recovery Vials

Seven Specifications of Headspace Vials You Need to Know

l Capacity (e.g., 6ml, 10ml, 20ml)

l ·Neck Diameter

l ·Septum Material (e.g., PTFE/Silicone, Butyl)

l ·Closure Type (Screw or Crimp)

l ·Vial Material (e.g., Borosilicate Glass)

l ·Bottom Shape (Flat or Rounded)

l ·Certified Cleanliness Level

Eight Features and Properties of Headspace Vials

l ·High Thermal Stability

l ·Resistance to Chemical Interactions

l ·Excellent Sealing Properties

l ·Optimal Sample Visibility (Clear vials)

l ·Protection from Light Degradation (Amber vials)

l ·Uniform Wall Thickness

l ·Precise Dimensional Tolerances

l·Low Background Contamination

How to Choose the Headspace Vials

When selecting headspace vials, consider the sample type, analysis requirements, and instrument compatibility. Assess factors such as capacity, closure type, and material compatibility to ensure optimal results.

How to Use A headspace vials? 8 Step Instructions

l Prepare the sample, ensuring it's appropriately homogenized.

l Transfer the sample into the headspace vial.

l Cap the vial securely.

l Place the vial in the headspace sampler tray.

l Set the desired parameters on the GC instrumen

l Inject the vial into the GC system.

l Allow the sample to equilibrate in the headspace.

l Extract the volatile fraction using a syringe.

What Is the Purpose of the 6-20ml Headspace Vials: 4 Points Need to Understand

l ·Instrument Compatibility: Ensuring compatibility with a broad spectrum of GC systems and autosamplers.

l ·Cost-Efficiency: Offering a balance between sample volume and consumables cost.

l ·Regulatory Compliance: Meeting the requirements of various analytical standards and guidelines.

l In essence, headspace vials represent a confluence of precision, versatility, and functionality in analytical chemistry. From their intricate manufacturing processes to their myriad applications, these vials stand as pillars of modern analytical methodologies, offering researchers and industries a gateway to the volatile world.

About ISO 9001:2015

ISO 9001:2015 is an international standard for quality management systems (QMS) established by the International Organization for Standardization (ISO). It sets out the criteria for a QMS and is based on several quality management principles, including a strong customer focus, the involvement of top management, a process approach, and continuous improvement.

Here are some key aspects of ISO 9001:2015:

Purpose:

The primary purpose of ISO 9001:2015 is to provide a framework for organizations to establish, implement, maintain, and continually improve a quality management system. The standard aims to enhance customer satisfaction by meeting customer requirements and delivering consistent, high-quality products or services.

Structure:

ISO 9001:2015 follows a structure known as the High-Level Structure (HLS), which is a common framework for all ISO management system standards. This structure includes ten clauses that cover various aspects of quality management, such as context of the organization, leadership, planning, support, operation, performance evaluation, and improvement.

Key Principles:

ISO 9001:2015 is based on several quality management principles, including:

1.Customer Focus: Organizations are required to understand and meet customer requirements and enhance customer satisfaction through the effective application of the quality management system.

2.Leadership: Top management is responsible for establishing a quality policy, ensuring that quality objectives are established, and demonstrating leadership and commitment to the quality management system.

3.Engagement of People: Employees at all levels should be competent, empowered, and engaged in achieving the organization's quality objectives.

4.Process Approach: The standard emphasizes the importance of understanding and managing interrelated processes as a system to achieve desired results.

5.Continuous Improvement: Organizations are encouraged to continually improve the suitability, adequacy, and effectiveness of the quality management system.

Certification:

Organizations can seek certification to ISO 9001:2015 by demonstrating compliance with the standard's requirements through an audit conducted by an accredited certification body. Certification provides third-party validation of an organization's commitment to quality and can enhance its credibility and reputation in the marketplace.

Benefits:

Implementing ISO 9001:2015 can bring several benefits to organizations, including:

l Improved product or service quality

l Enhanced customer satisfaction

l Increased operational efficiency

l Better risk management

l Competitive advantage

Access to new markets and business opportunities

In summary, ISO 9001:2015 is a globally recognized standard for quality management that provides a systematic approach to achieving consistent, high-quality products or services and continuous improvement. It is applicable to organizations of all sizes and industries and can serve as a foundation for building a culture of quality excellence and customer satisfaction.

AIJIREN COMPANY

Aijiren is a company known for manufacturing and supplying laboratory consumables, including a wide range of vials, chromatography columns, syringe filters, and other products used in analytical and research laboratories. Here are some key points about Aijiren:

Products and Services:

Aijiren offers a comprehensive portfolio of laboratory products designed for various applications in chromatography, sample preparation, and other laboratory processes. Their product range includes:

l Vials and Caps: Aijiren provides a variety of vials, including autosampler vials, headspace vials, and storage vials, along with compatible caps and closures.

l Chromatography Columns: Aijiren offers chromatography columns for liquid chromatography (LC) and gas chromatography (GC) applications, catering to different separation and analysis needs.

l Syringe Filters and Filtration Products: Aijiren manufactures syringe filters, membrane filters, and other filtration products for sample preparation and purification processes.

Laboratory Accessories: In addition to vials and chromatography products, Aijiren also supplies a range of laboratory accessories, including septa, crimping tools, and other consumables.

Quality and Compliance:

English

English

Chinese

Chinese

.jpg)

.jpg)