Craftsmanship of Chromatography Vials

Chromatography, a cornerstone in analytical sciences, relies heavily on the precision and reliability of its instruments and consumables. Among these, chromatography vials stand as silent yet crucial contributors to the symphony of analytical excellence. The craftsmanship involved in the creation of these vials is an art that goes beyond mere container production. In this exploration, we delve into the meticulous craftsmanship that defines chromatography vials, elevating them to the status of precision instruments.

1. Material Selection: The Art of Balance

At the core of craftsmanship lies the selection of materials. Chromatography vials are crafted with a keen understanding of the chemical landscape they will navigate. The choice between borosilicate glass and various polymer materials is a delicate dance between factors such as inertness, thermal stability, and resistance to chemical interactions.

The craftsmanship in material selection ensures that the vial becomes a harmonious partner in the chromatographic process, not introducing variables that could compromise the integrity of the sample.

2. Precision Manufacturing: Shaping Excellence

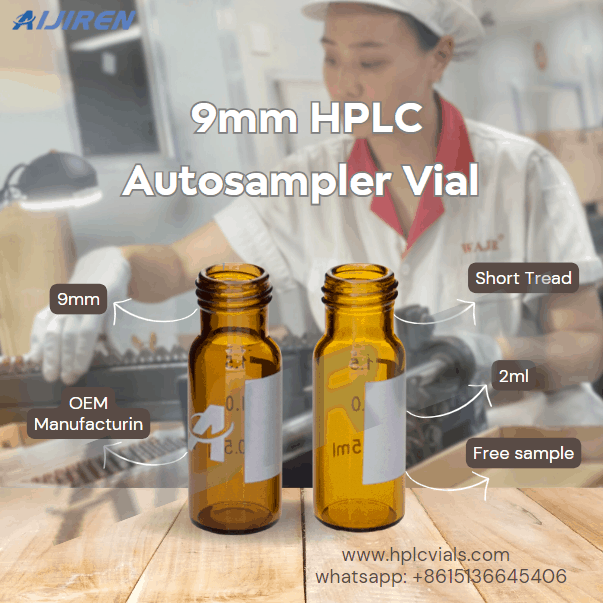

Craftsmanship in chromatography vials extends to the manufacturing process, where precision is paramount. The shaping of the vial involves intricate techniques to achieve consistent dimensions, ensuring compatibility with autosamplers and other chromatography instruments.

Whether it's the creation of vials with 8-425 screw necks or specialized designs like fused insert vials, the craftsmanship in manufacturing guarantees a symmetrical and flawless form, laying the foundation for reliable chromatographic performance.

3. Surface Treatment: Fine-Tuning Interactions

The inner surfaces of chromatography vials undergo meticulous surface treatments, adding another layer of craftsmanship to the equation. Silanization, for instance, involves modifying the vial's surface properties to minimize sample adsorption. This delicate treatment strikes a balance between hydrophobic and hydrophilic characteristics, preventing analytes from clinging to the vial walls.

Craftsmanship in surface treatment is an artistry that ensures precise results, especially in trace-level analyses where even the slightest interaction can influence outcomes.

4. Closure Systems: Ensuring Airtight Harmony

The closure system of chromatography vials is a masterpiece of craftsmanship, designed to provide an airtight seal that protects the sample from contamination and evaporation. Whether it's a screw cap, crimp cap, or snap cap, each closure system is crafted with precision to create a harmonious symphony of protection.

Craftsmanship in closure systems not only ensures the security of the sample but also guarantees ease of use, allowing scientists to seamlessly integrate vials into their analytical workflows.

5. Quality Control: The Conductor's Baton

The crafting of chromatography vials culminates in a meticulous quality control process, akin to a conductor guiding an orchestra. Every vial undergoes scrutiny to ensure it meets stringent standards for dimensions, material integrity, and surface characteristics.

Craftsmanship in quality control is the final act that determines whether the vial will contribute to the precision and reliability of chromatographic analyses. It ensures that each vial is a testament to the commitment to excellence in analytical science.

6. Innovative Designs: Pushing the Boundaries

Craftsmanship is not static; it evolves with innovation. Chromatography vials continually see the infusion of new designs and features, pushing the boundaries of what is possible. Fused insert vials, high-recovery vials, and other innovative designs are crafted with the intention of addressing specific challenges and enhancing overall performance.

Craftsmanship in innovation ensures that chromatography vials remain at the forefront of analytical advancements, adapting to the changing needs of scientists and laboratories.

Materials of Chromatography Vials

Chromatography vials, though often seen as simple containers, play a pivotal role in maintaining the integrity and precision of analytical processes. The materials used in these vials significantly impact sample stability, reproducibility, and overall analytical performance. In this exploration, we delve into the diverse materials of chromatography vials, understanding their unique properties and applications.

1. Borosilicate Glass: The Time-Tested Standard

Borosilicate glass stands as the traditional and most widely used material for chromatography vials. Renowned for its excellent chemical resistance and thermal stability, borosilicate glass ensures that the vial does not interfere with the sample. This type of glass is particularly suitable for high-performance liquid chromatography (HPLC) applications where precision and reliability are paramount.

One of the key advantages of borosilicate glass is its low expansion coefficient, which minimizes the risk of breakage due to sudden temperature changes during analysis. This characteristic makes borosilicate glass vials ideal for demanding applications in pharmaceuticals, environmental analysis, and clinical research.

2. Plastic Polymers: Versatility in Modern Chromatography

The advent of modern polymer materials has introduced a new dimension to chromatography vial design. Plastics such as polypropylene (PP) and polyethylene terephthalate (PET) offer advantages like reduced weight, lower cost, and resistance to breakage. While plastic vials may not match borosilicate glass in terms of inertness, advancements in polymer technology have significantly improved their chemical resistance.

Polypropylene vials, for instance, are well-suited for less demanding applications and can be an excellent choice when cost-effectiveness is a priority. However, it's crucial to consider the compatibility of the plastic material with the specific analytes to prevent any undesirable interactions that may affect the accuracy of results.

3. Polymer-Coated Glass: Enhancing Chemical Resistance

Polymer-coated glass vials offer a fusion of the robustness of glass and the enhanced chemical resistance provided by various polymer coatings. These coatings act as a protective layer, reducing the chances of sample interactions with the vial surface.

Common polymer coatings include polyvinyl chloride (PVC) and polytetrafluoroethylene (PTFE). PVC coatings enhance the vial's resistance to acidic or basic samples, while PTFE coatings provide exceptional inertness. Polymer-coated glass vials find applications in situations where specific chemical resistance is crucial, such as the analysis of highly corrosive substances.

4. Fused Insert Vials: Merging the Best of Both Worlds

Fused insert vials integrate a glass insert within a plastic or glass outer vial. This design aims to combine the inertness of glass with the versatility of plastic. The glass insert, typically made from borosilicate glass, serves as a liner, preventing the sample from coming into contact with the vial walls.

Fused insert vials are particularly advantageous when dealing with trace-level analyses, where sample adsorption can significantly impact sensitivity. This design minimizes the risk of sample loss and provides an efficient solution for a wide range of chromatographic applications.

In the realm of chromatography, the choice of vial material is far from a one-size-fits-all decision. Each material brings its own set of advantages and considerations, allowing users to tailor their selection based on the specific requirements of their analytical methods.

Specifications of Chromatography Vials

Chromatography vials serve as the foundation of analytical workflows, playing a critical role in maintaining sample integrity and precision. The specifications of these vials are key determinants of their performance in diverse chromatographic techniques. In this in-depth exploration, we unravel the intricacies of chromatography vial specifications, shedding light on the critical elements that define their functionality.

1. Vial Size and Volume: Crafting the Perfect Fit

One of the fundamental specifications of chromatography vials is their size and volume capacity. Vials are available in various sizes, ranging from microscale to macro, catering to the diverse needs of analytical applications. The choice of vial size depends on factors such as sample volume, injection volume, and the sensitivity of the analytical technique.

Microscale vials, typically with capacities ranging from 0.1 to 0.5 mL, are ideal for applications requiring minimal sample consumption, such as high-sensitivity mass spectrometry. Macro vials, on the other hand, with capacities exceeding 2 mL, find utility in applications demanding larger sample volumes, such as preparative chromatography.

2. Closure Systems: Securing Sample Integrity

The closure system of chromatography vials is a critical specification that ensures the hermetic sealing of the vial, preventing sample contamination and evaporation. Various closure systems are employed, including screw caps, crimp caps, and snap caps, each offering distinct advantages.

Screw caps provide a secure and convenient sealing mechanism, offering ease of use and compatibility with automated systems. Crimp caps, on the other hand, involve the use of a crimping tool to secure the cap, ensuring a tight seal. Snap caps feature a simple snap-on design, facilitating quick and easy access to the sample.

3. Septa Selection: Barrier Against Contamination

Septa, the seals placed within the cap, act as a barrier between the sample and the external environment. The choice of septa material is crucial to prevent sample contamination and ensure consistent analytical results. Common septa materials include silicone, PTFE (polytetrafluoroethylene), and rubber.

Silicone septa are widely used for their inertness and resilience, making them suitable for a broad range of applications. PTFE septa exhibit excellent chemical resistance and are often preferred for demanding analyses involving aggressive samples. Rubber septa are chosen for applications where a tight seal is critical.

4. Surface Treatment: Mitigating Sample Adsorption

The vial's inner surface treatment is a specification that directly influences sample adsorption. To minimize interactions between the sample and the vial walls, surface treatments such as silanization are employed. Silanized vials feature a thin layer of silane coating, modifying the surface properties to be either hydrophobic or hydrophilic.

Silanization is particularly beneficial in trace-level analyses where sample adsorption can significantly impact sensitivity. By tailoring the vial's surface characteristics, this specification ensures accurate and reproducible results in chromatographic separations.

5. Color: Protecting Light-Sensitive Samples

The color of chromatography vials is a specification that goes beyond aesthetics, playing a crucial role in protecting light-sensitive samples. Amber or brown-colored vials are commonly employed to shield samples from the degrading effects of ultraviolet (UV) and visible light.

UV-sensitive compounds, such as certain pharmaceuticals or environmental pollutants, can undergo degradation when exposed to light. Amber vials act as a protective shield, preserving sample stability and integrity during storage and analysis.

6. Graduation Marks: Facilitating Accurate Volume Measurement

Graduation marks are an essential specification for vials, providing a visual indicator of the sample volume within the vial. Accurate volume measurement is crucial for precise sample preparation and injection in chromatographic analyses.

Vials are often marked with calibrated lines, allowing users to measure and dispense precise volumes. These graduation marks enhance the reproducibility of sample preparation, ensuring consistency in analytical results across experiments.

7. Certifications: Ensuring Quality and Compliance

Certifications and compliance with industry standards are critical specifications that speak to the quality and reliability of chromatography vials. Vials manufactured in adherence to international standards, such as ISO or ASTM, instill confidence in users regarding their performance and suitability for various applications.

Additionally, vials designed for specific applications, such as pharmaceutical analyses, may carry certifications ensuring compliance with regulatory requirements. Certifications are a testament to the vial's quality, reliability, and adherence to stringent manufacturing standards.

In the intricate world of chromatography, the specifications of vials serve as the blueprint for analytical success. From size and closure systems to surface treatments and certifications, each specification plays a crucial role in ensuring sample integrity, precision, and consistency.

Application of chromatography vials

1. Pharmaceutical Precision with Chromatography Vials

In the dynamic world of pharmaceuticals, where the development and manufacturing of medications demand unwavering precision, chromatography vials emerge as silent sentinels, safeguarding the integrity of critical samples. Crafted with meticulous attention to detail, these vials become indispensable tools in pharmaceutical laboratories, contributing to the assurance of medication quality and efficacy.

The pharmaceutical industry operates under stringent regulations, where the accuracy of analytical results directly influences the safety and effectiveness of medications. Chromatography vials, typically made from premium materials like borosilicate glass, are chosen for their inertness and stability. This material ensures that the vial itself does not introduce contaminants or interfere with the pharmaceutical sample during analysis, maintaining the purity of the medication under scrutiny.

Compatibility with various autosamplers is a hallmark of the craftsmanship behind chromatography vials in the pharmaceutical realm. The vials are precisely designed to seamlessly integrate into automated systems, allowing for high-throughput analyses. This integration not only enhances the efficiency of pharmaceutical laboratories but also reduces the risk of human error, a critical consideration in the pursuit of precision.

The closure systems of these vials, whether screw caps, crimp caps, or snap caps, are crafted to create an airtight seal, preventing sample evaporation and contamination. This hermetic sealing is crucial in pharmaceutical quality control, where even minute variations can impact the composition of medications.

Chromatography vials contribute significantly to pharmaceutical research and development, aiding in the analysis of raw materials, intermediates, and final products. Whether determining the concentration of active pharmaceutical ingredients or detecting impurities, these vials provide a secure environment for the precise separation and quantification of compounds.

In the pharmaceutical laboratory, where the stakes are high and precision is paramount, the craftsmanship embedded in chromatography vials becomes a cornerstone of analytical success. These vials ensure that pharmaceutical scientists can rely on accurate and reproducible results, ultimately contributing to the creation of medications that meet the highest standards of safety and efficacy.

2. Chromatography Vials in Environmental Analysis

In the realm of environmental analysis, where the health of ecosystems and human well-being hang in the balance, chromatography vials emerge as stalwart guardians, ensuring the accuracy and reliability of data crucial for understanding environmental impacts. Crafted with precision and designed to meet the unique challenges of analyzing diverse environmental samples, these vials play a pivotal role in safeguarding the planet.

Chromatography vials become essential tools in the meticulous analysis of water, soil, and air samples, contributing to our understanding of pollutants and their effects on the environment. Crafted from materials such as borosilicate glass, these vials exhibit high chemical resistance, ensuring that the vial itself does not introduce contaminants that could compromise the integrity of environmental samples.

One of the key attributes that make chromatography vials environmental guardians is their inertness, which prevents the vial from interacting with analytes during analysis. This is especially critical in environmental studies, where trace-level concentrations of pollutants must be accurately detected and quantified. The craftsmanship behind these vials ensures that the results reflect the true composition of environmental samples, allowing scientists to make informed decisions regarding conservation and remediation efforts.

The compatibility of chromatography vials with a variety of analytical techniques, such as gas chromatography and liquid chromatography, adds to their versatility in environmental analysis. This adaptability enables scientists to choose the most suitable method for their specific environmental monitoring needs, from detecting pesticides in water to analyzing air quality for volatile organic compounds.

As the stewards of the environment seek to address global challenges such as climate change and pollution, chromatography vials stand as silent sentinels, enabling precise measurements that drive informed environmental policies. Their craftsmanship ensures that environmental scientists can rely on accurate data to assess the impact of human activities on the planet, ultimately contributing to the preservation of ecosystems for future generations.

3. Chromatography Vials in Food and Beverage Quality Control

In the world of gastronomy, where flavors dance on the palate and safety is paramount, chromatography vials emerge as unsung heroes in ensuring the highest standards of quality and purity. Crafted with precision, these vials play a vital role in the realm of food and beverage quality control, contributing to the creation of delectable delights and the assurance of consumer safety.

Chromatography vials become essential instruments in the meticulous quality control processes of the food and beverage industry. Whether it's analyzing the composition of ingredients, detecting contaminants, or verifying the authenticity of flavors, these vials provide a secure environment for precise chromatographic separations. Crafted from materials like borosilicate glass, they ensure that the vial itself remains inert, preventing any interference with the delicate flavors and aromas under examination.

One of the key attributes that make chromatography vials indispensable in culinary applications is their compatibility with various analytical techniques. From gas chromatography to liquid chromatography, these vials accommodate a spectrum of methods, allowing food scientists to choose the most suitable approach for their specific analyses. This adaptability is crucial in addressing the diverse challenges posed by the intricate matrix of food and beverage samples.

Craftsmanship in the design of chromatography vials extends to their closure systems. Whether screw caps for convenience or crimp caps for a secure seal, these closures ensure the hermetic containment of samples, preventing evaporation and maintaining the integrity of volatile compounds. In an industry where precision is synonymous with quality, the airtight seal provided by these vials is paramount.

As culinary artisans push the boundaries of flavor and consumers demand transparency in food sourcing, chromatography vials become instruments of assurance. Their craftsmanship guarantees that the flavors created in the kitchen meet rigorous quality standards, and that every sip and bite is an experience crafted with precision and care. In the realm of culinary excellence, chromatography vials are silent guardians, ensuring that the art of gastronomy remains a fusion of indulgence and safety.

4. Clinical Diagnostics Precision with Chromatography Vials

In the realm of clinical diagnostics, where accuracy is paramount for informed medical decisions, chromatography vials emerge as essential instruments in the quest for precision. Crafted with meticulous attention to detail, these vials contribute significantly to the reliability of diagnostic results, ensuring that healthcare professionals can trust the accuracy of their analyses.

Chromatography vials become guardians of sample integrity in clinical diagnostics laboratories, where the analysis of biological specimens is a critical step in the diagnostic process. Crafted from premium materials such as borosilicate glass, these vials maintain the purity of biological samples, ensuring that the vial itself does not introduce contaminants that could compromise the accuracy of test results.

Compatibility with various autosamplers is a hallmark of the craftsmanship behind chromatography vials in the clinical diagnostics realm. The precisely engineered design of these vials allows for seamless integration into automated systems, streamlining diagnostic workflows and reducing the risk of human error. This integration is especially crucial in clinical laboratories where efficiency and precision are of the essence.

The closure systems of chromatography vials, whether screw caps, crimp caps, or snap caps, are crafted with the utmost precision to create a secure seal. This hermetic sealing is vital in preventing sample evaporation and contamination, ensuring that biological samples are preserved in their original state during analysis. In clinical diagnostics, where even the smallest variation can impact the accuracy of results, the craftsmanship behind vial closures becomes a critical factor in maintaining the integrity of diagnostic samples.

Chromatography vials are instrumental in the analysis of a wide range of biological samples, from blood and urine to cerebrospinal fluid. Whether quantifying biomarkers, detecting disease indicators, or monitoring therapeutic drug levels, these vials provide a reliable platform for precise chromatographic separations. The craftsmanship behind their design ensures that clinical diagnostics professionals can rely on accurate and reproducible results, ultimately contributing to the early detection and effective management of diseases.

In the arena of clinical diagnostics, where every result carries significant implications for patient care, chromatography vials stand as beacons of precision. Their craftsmanship elevates healthcare accuracy, empowering clinicians with the confidence to make informed decisions and improving the overall quality of patient outcomes.

5. Chromatography Vials in Biomarker Discovery

In the realm of cutting-edge research, where scientists aim to unravel the mysteries of diseases and unlock the potential of personalized medicine, chromatography vials play a pivotal role in biomarker discovery. Crafted with precision, these vials become the canvas upon which groundbreaking discoveries in diagnostics and therapeutic advancements are painted.

Biomarkers, indicators of biological processes or conditions, are the linchpin of modern medical research. Chromatography vials, meticulously designed and engineered, provide the foundation for the separation and analysis of complex biological samples critical for biomarker discovery.

The craftsmanship behind chromatography vials becomes evident in their ability to maintain sample integrity during the analytical process. Crafted from materials like borosilicate glass, these vials ensure that the vial itself does not introduce contaminants or interfere with the delicate biomolecules under examination. This level of purity is indispensable in the pursuit of identifying biomarkers that can serve as diagnostic indicators or therapeutic targets.

The compatibility of chromatography vials with sensitive analytical techniques, including liquid chromatography-mass spectrometry (LC-MS) and gas chromatography-mass spectrometry (GC-MS), positions them at the forefront of biomarker research. The precision in their design allows scientists to achieve the high-resolution separations necessary for detecting and quantifying low-abundance biomolecules in complex biological matrices.

In biomarker discovery, where the goal is to discern subtle changes in biological samples that could signify disease states or treatment responses, the hermetic sealing provided by chromatography vials is paramount. This airtight seal prevents sample evaporation and maintains the stability of volatile biomolecules, ensuring the reproducibility and accuracy of results.

As researchers delve into the intricacies of the human body at the molecular level, chromatography vials become enablers of breakthroughs. Their craftsmanship ensures that every separation, every analysis, contributes to the precision required for biomarker discovery. In the hands of scientists pushing the boundaries of medical knowledge, chromatography vials become silent partners in the journey toward more effective diagnostics, personalized treatments, and a deeper understanding of human health.

6. Chromatography Vials in Crime Scene Analysis

In the fascinating realm of forensic science, where every clue holds the potential to solve a mystery, chromatography vials take center stage, unveiling the secrets hidden within crime scene samples. Crafted with meticulous precision, these vials become indispensable tools for forensic analysts, ensuring the accuracy and reliability of evidence analysis that can make or break a case.

Chromatography vials play a critical role in preserving the integrity of samples collected from crime scenes. The craftsmanship behind these vials ensures that they are inert and do not introduce contaminants that could compromise the forensic evidence. Whether analyzing blood, urine, or other bodily fluids, the purity maintained by chromatography vials becomes paramount in uncovering the truth concealed within the samples.

Compatibility with a range of analytical techniques positions chromatography vials at the forefront of forensic investigations. From gas chromatography to liquid chromatography, these vials accommodate the diverse nature of forensic samples, allowing analysts to select the most suitable method for the analysis of drugs, poisons, and other trace substances. The precision in their design facilitates the separation of complex mixtures, enabling the identification of specific compounds crucial to solving criminal cases.

In crime scene analysis, where the goal is to reconstruct events and establish timelines, the secure closure systems of chromatography vials play a pivotal role. Crafted with the utmost precision, the closure systems ensure an airtight seal, preventing sample contamination and evaporation. This is especially critical when dealing with volatile substances or when preserving evidence for extended periods.

The versatility of chromatography vials extends to their use in analyzing arson residues, gunshot residues, and other materials pivotal in criminal investigations. The meticulous craftsmanship behind these vials contributes to the reliability of forensic results, helping forensic scientists unravel the complexities of crime scenes.

As forensic analysts strive to unveil the truth concealed within the smallest traces of evidence, chromatography vials become the unsung heroes of crime scene analysis. Their precision, purity, and compatibility with advanced analytical techniques empower forensic scientists in their quest for justice, ensuring that every clue is scrutinized with the accuracy required to solve even the most perplexing cases.

7. Chromatography Vials in Oil and Gas Analysis

In the intricate realm of the petrochemical industry, where the quality and composition of oil and gas products determine success, chromatography vials play an indispensable role as guardians of precision. Crafted with meticulous detail, these vials serve as the cornerstone in oil and gas analysis, ensuring the accuracy and reliability of results that influence critical decisions in exploration, production, and distribution.

Chromatography vials, engineered from materials like borosilicate glass, exhibit an unwavering commitment to sample purity. The vials' construction prevents any interference, maintaining the pristine nature of samples crucial for accurate analyses. In an industry where even trace impurities can impact product quality, the craftsmanship of chromatography vials becomes paramount.

Versatility is another hallmark of these vials, with compatibility across a range of analytical techniques. Whether employed in gas chromatography for volatile hydrocarbons or liquid chromatography for intricate matrices, these vials provide a reliable platform for the separation and quantification of components. Their precise design allows petrochemical scientists to achieve high-resolution separations, essential for identifying specific compounds in challenging samples.

As guardians of accuracy, the hermetic sealing of chromatography vials safeguards against sample evaporation, preserving the stability of volatile compounds during analysis. This attention to detail ensures that results faithfully represent the composition of oil and gas samples. Chromatography vials, with their craftsmanship, stand as silent sentinels in the pursuit of precision, contributing significantly to the quality control processes that drive the success of the petrochemical industry.

8. Chromatography Vials in Educational Laboratories

Within the realm of educational laboratories, where future scientists embark on their analytical journeys, chromatography vials emerge as educational catalysts, fostering a hands-on understanding of chromatographic principles. Crafted for simplicity without compromising precision, these vials become instrumental tools in shaping the academic prowess of budding scientists.

Chromatography vials, designed with educational objectives in mind, provide a tangible platform for students to explore separation techniques. Their user-friendly features, from easy-to-use closures to compatibility with various chromatography setups, empower students to grasp the fundamentals of chromatography without being overwhelmed by complexity. Crafted from durable materials, such as borosilicate glass, these vials withstand the rigors of educational experiments, ensuring longevity in the learning process.

The versatility of chromatography vials allows them to be integrated into a spectrum of educational exercises, from basic separation experiments to more advanced analytical techniques. Students gain practical insights into the principles of chromatography, learning how to apply these techniques to analyze complex mixtures, identify components, and solve real-world problems.

As vessels of knowledge, chromatography vials, with their crafted simplicity and functionality, inspire academic curiosity. They play a pivotal role in nurturing the academic prowess of students by providing a tangible link between theoretical concepts and practical applications, preparing the next generation of scientists for the challenges of analytical science with confidence and competence.

Chromatography Vial Handling and Storage

In the intricate realm of chromatography, where precision is paramount, the handling and storage of chromatography vials are crucial aspects that significantly impact the reliability of analytical results. From sample integrity to experimental reproducibility, proper vial handling and storage play a pivotal role in ensuring the success of chromatographic analyses.

1. Vial Selection and Inspection

Selecting the appropriate chromatography vial is the first step towards reliable results. The choice between screw cap, crimp cap, or snap cap vials depends on the specific requirements of the analysis. Vials should be inspected for defects such as chips, cracks, or contamination before use. Crafted from materials like borosilicate glass, these vials are chosen for their inertness and stability, minimizing the risk of interference with the sample.

2. Cleaning and Pre-treatment

The cleaning and pre-treatment of chromatography vials are critical steps in the analytical process, laying the foundation for accurate and reproducible results. These meticulous procedures are designed to eliminate any potential sources of contamination, ensuring the purity of the sample and the integrity of chromatographic analyses.

Ⅰ. Cleaning Procedures: Before use, chromatography vials should undergo thorough cleaning to remove residues or contaminants that could interfere with analytical precision. Cleaning typically involves rinsing the vials with solvents compatible with the analysis. This step is particularly crucial when transitioning between different sample types or analyses to prevent cross-contamination.

Ⅱ. Pre-treatment Protocols: Certain samples may require specific pre-treatment steps to enhance the reliability of chromatographic results. For example, when analyzing samples prone to adsorption or interaction with the vial surface, a pre-treatment process may involve coating the vial interior with a suitable material to minimize these interactions. This additional step contributes to more accurate separations and quantifications.

Ⅲ. Solvent Selection: The choice of cleaning solvents is pivotal in the pre-treatment process. Solvents should be selected based on their ability to dissolve potential contaminants without leaving residues that could impact subsequent analyses. Commonly used solvents include high-purity water, methanol, acetonitrile, or a mixture of these, depending on the specific requirements of the analysis.

Ⅳ. Drying Procedures: After cleaning, vials should be thoroughly dried to eliminate any residual solvent, preventing its introduction into the sample during sample preparation or analysis. Proper drying procedures, such as air-drying or nitrogen purging, contribute to maintaining the integrity of the vial and the purity of the subsequent sample.

Ⅴ. Validation of Cleaning Procedures: To ensure the effectiveness of cleaning and pre-treatment processes, validation steps are often implemented. This may include running blank samples through the entire analytical process to confirm the absence of contaminants originating from the vial. Validation protocols add an extra layer of confidence in the reliability of the vials for subsequent analyses.

3. Handling Techniques

Precision in vial handling is paramount to prevent contamination and maintain sample integrity. Always handle vials with clean gloves to avoid introducing oils or particles from the skin. The use of clean, non-shedding wipes and tools is recommended during sample transfer to minimize the risk of introducing extraneous matter.

4. Cap Handling and Sealing

Whether utilizing screw caps, crimp caps, or snap caps, proper handling and sealing are critical. Screw caps should be tightened securely but not over-torqued to avoid damage. Crimp caps require careful application to ensure a proper seal without over-deforming the cap. Snap caps should be firmly engaged to prevent evaporation. The hermetic sealing provided by these caps is essential in preserving sample integrity during storage and analysis.

5. Storage Conditions

Chromatography vials should be stored under appropriate conditions to maintain the stability of samples. For volatile compounds, low-temperature storage may be necessary to minimize evaporation. Dark storage conditions protect light-sensitive samples. Additionally, proper labeling with information such as sample ID, date, and storage conditions aids in traceability and ensures that the correct vials are used for subsequent analyses.

6. Avoiding Sample Cross-Contamination

To prevent sample cross-contamination, dedicated vials should be used for each sample. Thorough cleaning of tools and equipment between samples is essential. Proper storage and organization of vials, whether in racks or trays, further reduce the risk of accidental mix-ups during the analytical process.

7. Transportation Precautions

When transporting chromatography vials, especially for fieldwork or remote analyses, secure packaging is vital. Specialized carriers or protective cases help prevent breakage and ensure that vials arrive at the destination in optimal condition.

HPLC Vial Innovations and Future Trends

In the dynamic landscape of High-Performance Liquid Chromatography (HPLC), vial innovations continue to shape the future of analytical science. Recent advancements focus on enhancing precision through novel materials, such as inert polymers, and introducing user-friendly features for seamless integration with automated systems. Future trends forecast even greater emphasis on sustainability, with the development of eco-friendly vial options. Additionally, smart vial technologies, incorporating RFID tags for sample tracking and data integration, are poised to revolutionize HPLC workflows. These innovations collectively promise to elevate analytical capabilities, streamline processes, and contribute to a more sustainable and connected analytical future.

English

English

Chinese

Chinese

.jpg)