Oct. 20th, 2021

Septa, caps and liners play a key role in the storage and preparation of samples. They securely seal samples from the external environment while simultaneously allowing injection by sampling needles.

Aijiren cap septa offers new septum materials and unique processes to improve septum sealing integrity and reduce the risk of sample contamination.

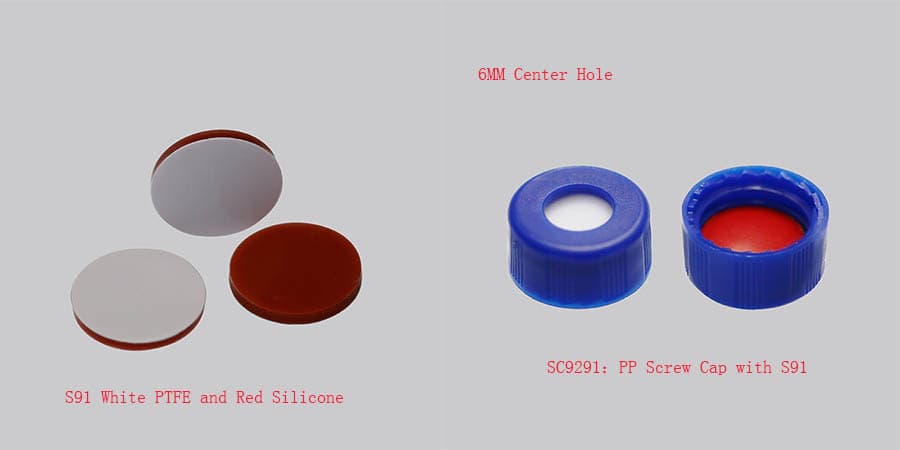

Septa are 0.035” Natural Silicone with 0.005” Natural PTFE. High quality silicone is used to ensure proper re-sealing and reduced coring. Designed for multiple injections and/or longer sample cycles, for both GC and LC applications. Absence of pigments eliminates additional sources of contamination.

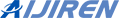

Cap are high-quality durable polypropylene, with ribbed sides for ease in handling. Standard colors are yellow, blue, and black.

Septa suitability with chemicals

The table below summarizes the suitability of each septa material with a range of chemicals, this can vary based on factors such as temperature, molecular weight and solvent concentration.

|

PTFE

|

PTFE/silicone

|

PTFE/silicone/PTFE

|

Viton

|

Silicone

|

Silicone/FEP

|

Silicone/polyimide

|

Butyl

|

Foam (PTFE/polyethene foam)

|

|

Acetonitrile

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

✓

|

|

|

Hydrocarbons

|

✓

|

|

✓

|

|

✓

|

✓

|

✓

|

|

|

Methanol

|

✓

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

✓

|

|

Benzene

|

✓

|

|

✓

|

✓

|

|

✓

|

✓

|

|

|

THF

|

✓

|

|

✓

|

|

|

✓

|

✓

|

|

|

Toluene

|

✓

|

|

✓

|

|

|

✓

|

✓

|

|

|

DMF

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

✓

|

✓

|

|

DMSO

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

|

|

|

Ether

|

✓

|

✓

|

✓

|

|

|

✓

|

✓

|

|

|

DCM

|

✓

|

|

✓

|

✓

|

|

✓

|

✓

|

|

|

Alcohols (ethanol)

|

✓

|

✓

|

✓

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Acetic acid

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

✓

|

✓

|

|

Acetone

|

✓

|

✓

|

✓

|

✓

|

|

✓

|

✓

|

✓

|

|

Phenol

|

✓

|

✓

|

✓

|

|

|

✓

|

✓

|

✓

|

|

Cyclohexane

|

✓

|

|

✓

|

|

|

✓

|

✓

|

|

Red PTFE/White Silicone, 0.040"Septa are 0.035” White Silicone with 0.005” Red PTFE. High quality silicone is used to ensure proper re-sealing and reduced coring. Designed for multiple injections and/or longer sample cycles - for both GC and LC applications.

A poor quality septum may lead to improper re-sealing, skewed test results, or poor quality product. To minimize this, manufacturing inputs must be strictly controlled.

Septa compatibility with applications

This table provides a summary of the suitability of our septa materials to a variety of applications.

|

PTFE

|

PTFE/silicone

|

PTFE/silicone/PTFE

|

Viton

|

Silicone

|

Silicone/FEP

|

Silicone/polyimide

|

Butyl

|

Natural rubber

|

|

Temperature range

|

Up to 260°C

|

-40°C to 250°C

|

-40°C to 250°C

|

-40°C to 260°C

|

-40°C to 250°C

|

-40°C to 250°C

|

-40°C to 300°C

|

-50°C to 150°C

|

|

Multiple injections

|

No

|

Yes

|

Yes

|

No

|

Yes

|

Yes

|

Yes

|

No

|

|

Price

|

Very economical

|

Economical

|

Most expensive

|

Economical

|

Very economical

|

Economical

|

Expensive

|

Economical

|

|

Suitable for storage

|

No

|

Yes

|

Yes

|

No

|

Yes

|

Yes

|

Yes

|

No

|

|

Best for

|

· Superior chemical inertness

· Single injections

· Short cycle times

|

· Most common HPLC and GC analyses

· Not suitable for chlorosilanes

|

· Ultra analysis

· Repeat injections

· Internal standards

|

· Chlorinated solvents

· High temperatures

· Limited resealing, not suitable for multiple injections

|

· General purpose

|

· Highest chemical compatibility

|

· Sample sensitive to PTFE exposure

· High temperature

|

· Organic solvents

· Acetic acids

· Impermeable to gases

|

For users of chromatographic data,maintaining integrity of the analytical results from collection to analysis is of the utmost importance. Too often unintended contaminants are introduced thus biasing analytical results. Contamination from septa can be one source of data biasing. Aijiren has always manufactured septa using a platinum curing process, which is the highest quality process in the manufacture of chromatography septa.

Cap is generally made of polypropylene, the raw materials go through the mold press in high temperature. On the outside of cap, there are some knurled lines, which can facilitate the grasping of the robot arm; On the other hand, the knurled lines can strengthened structural strength of Screw cap.

Aijiren is your assurance of unsurpassed vial cap septa and liner sealing integrity. Aijiren’s wide choice of materials (both upper and lower barriers as well as elastomers), thicknesses and durometer measurement offer you the ideal combinations for your various sealing applications. And our unique adhesive-free bonding process means that septa and cap liners will stay put and provide an environment with no possibility of adhesive contamination. CepureSecure means a septum that keeps its promises time and again, improving your results and lowering your overall cost of operation.

|

Cap Type

|

Characteristic

|

|

Screw caps

|

- Often used for LC and LC/MS.

- Provide an airtight seal.

- For automation, magnetic screw caps are advantageous because they are less likely to become rounded over time, providing increased surface area for the magnets used to move the vials.

- This decreases the risk of any vials falling from the magnet.

|

|

Snap caps

|

- Simple snap design when crimping tool is not available.

- Easy removal without special tools.

|

|

Crimp caps

|

- Crimp caps provide extra security for studies where it is important to avoid contamination or sample tampering.

- Can become rounded when crimped onto a vial, resulting in less surface area for magnets to stick to during automation.

- Require crimper/decrimper, can cause septa distortion if over crimped.

|

Our experience with and knowledge of different materials gives us an edge. Over the years, we have worked with all types of silicone, organic polymers (e.g. natural rubber and butyl), and different types of plastics too. Our focus is to develop the best possible formulation for the application. We welcome custom inquiries for unique vial cap and injection port septa, especially when the standard parts in the marketplace won't do.

What Aijiren Tech can Custom:

Cap types: Crimp, screw, snap, cap.

Cap materials: Polypropylene, aluminum,

Cap color: Standard colors are yellow, blue, and black and other.

Septa liner and film materials: Silicone, silicone with PTFE

Septa thickness range: 0.25 mm to 3 mm.

Septa configurations: Non slit, straight slit, star slit, cross slit, Y-cut.

English

English

Chinese

Chinese